PCC vs RCC: Full Form, Meaning, Mix Ratio & Key Differences Explained

Concrete is everywhere. You walk on it. You live inside it. You drive over it.

But here is something most people do not realize. The concrete under your feet is not the same as the concrete holding up a bridge. They look similar. Grey. Hard. Solid. But they are built differently.

In construction, we use two main types of concrete. One is called PCC. The other is RCC.

Think of it like a team. One player is strong but does only one job. The other player is versatile and handles pressure from all sides. Both are needed. Both matter.

If you are a civil engineering student, a site engineer, or just someone trying to understand how buildings stand tall, this guide is for you. We will break down the difference between PCC and RCC. No fluff. No unnecessary jargon. Just clear, practical knowledge you can use on site or in an exam.

Let us start at the very beginning.

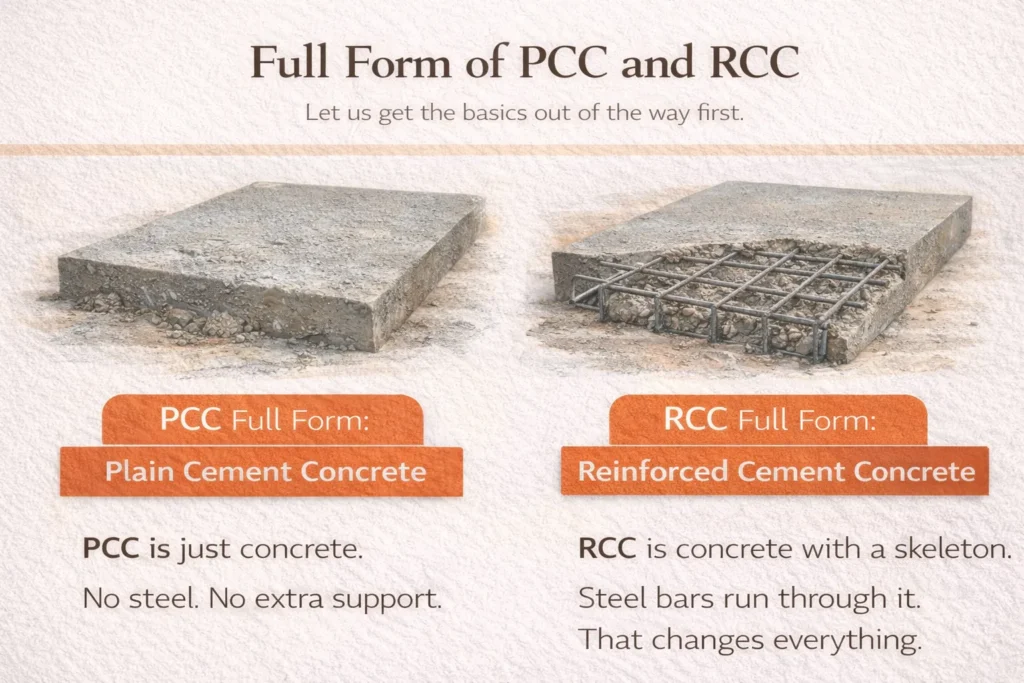

Full Form of PCC and RCC

Let us get the basics out of the way first.

PCC Full Form: Plain Cement Concrete

RCC Full Form: Reinforced Cement Concrete

In civil engineering, these two terms come up constantly. If you are preparing for a government exam or a site interview, knowing the full form is the first step. But the real test is understanding what these words actually mean.

PCC is just concrete. No steel. No extra support.

RCC is concrete with a skeleton. Steel bars run through it. That changes everything.

What is PCC?

PCC stands for Plain Cement Concrete.

It is a simple mixture. You take cement. You add sand. You add coarse aggregate like crushed stone. You mix it with water. That is it.

No steel bars. No reinforcement. Just concrete.

Here is how to remember it. PCC is the mat. Not the table. The mat sits under the table legs. It creates a flat, stable surface. But the mat itself does not hold heavy weight from above.

That is exactly what PCC does in construction. It creates a clean, level bed. It spreads the load evenly. It protects the soil from moisture. But it does not carry the main structural load.

Common PCC mix ratios:

- 1:4:8 – For levelling courses and general base work

- 1:3:6 – For flooring bases and pavements

- 1:5:10 – For mass fill and foundation bedding

The numbers mean cement : sand : aggregate. So 1:4:8 means 1 part cement, 4 parts sand, 8 parts aggregate.

What is RCC?

RCC stands for Reinforced Cement Concrete.

This is concrete with muscle. You take the same basic mixture of cement, sand, aggregate, and water. But before you pour it, you place steel reinforcement bars inside a mould.

These steel bars are called rebars. They are strong. They can bend without snapping. Concrete, on its own, is great at handling weight pushing down on it. That is compression. But it cracks easily when something pulls on it. That is tension.

Steel fixes that problem.

Imagine holding a heavy book with just your palms facing up. You can hold it fine. Now try holding the same book with your palms facing down, gripping the cover. Your fingers will ache quickly. Concrete is like your palms. Strong one way. Weak the other. Steel gives it grip.

Common RCC mix grades:

- M20 (1:1.5:3) – Standard for residential slabs and beams

- M25 – Design mix for columns and heavier loads

- M30 and above – High-strength for bridges and high-rises

Unlike PCC, higher grades of RCC are usually design mixes. That means the exact proportion is calculated in a lab based on the strength required. You do not just guess the ratio.

Difference Between PCC and RCC

Let us put them side by side. This is the heart of the topic.

| Parameter | PCC | RCC |

|---|---|---|

| Full form | Plain Cement Concrete | Reinforced Cement Concrete |

| Reinforcement | No steel | Steel bars provided |

| Strength | Low compressive strength | High compressive + tensile strength |

| Load bearing | Cannot carry heavy structural loads | Designed to carry full loads |

| Cost | Lower | Higher (steel + labour) |

| Usage | Base work, flooring, levelling | Columns, beams, slabs, footings |

| Cracking | Cracks under tension | Resists cracking due to steel |

| Design life | 20–30 years | 50–100 years with proper cover |

Here is the simplest way to explain it.

PCC is the foundation bed. It makes sure the ground is flat and clean.

RCC is the skeleton. It holds the building upright.

Both are essential. One cannot replace the other.

PCC Mix Ratio: When to Use What

On site, you will hear supervisors call out numbers. “Give me 1:4:8 for the floor bed.” “This footing needs 1:5:10.”

These are not random. Each ratio has a specific job.

1:4:8 PCC Mix

- Used for levelling course below foundation

- Low cement content

- Economical for large areas

- Minimum strength requirement

1:3:6 PCC Mix

- Used for flooring base and pavements

- More cement than 1:4:8

- Provides better binding

- Suitable for light load surfaces

1:5:10 PCC Mix

- Used for mass concrete works

- Very lean mix

- Only for non-structural filling

- Rare in modern residential work

Here is a tip from someone who has spent time on site. Never let the contractor add extra water to PCC just to make it flow easily. Excess water kills the strength. The mix should be workable but not soupy.

RCC Mix Ratio: Grades Explained

RCC is not mixed by guesswork on most large projects. You follow a grade. M20. M25. M30.

The M stands for Mix. The number is the characteristic compressive strength in N/mm². So M20 concrete can safely take 20 Newtons per square millimetre of pressure after 28 days of curing.

M20 Grade (1:1.5:3)

- Most common for residential construction

- Used for slabs, beams, columns in houses

- Sufficient for 2–4 storey buildings

M25 Grade

- Higher strength

- Often a design mix

- Used for larger columns and heavy loads

M30 and above

- Used for bridges, high-rise towers, industrial structures

- Requires strict quality control

- Not needed for typical home construction

I once saw a contractor try to use M15 for a roof slab to save money. The structural engineer rejected it immediately. You do not compromise on RCC grades. It is not about saving a few thousand rupees. It is about the building staying upright for decades.

Uses of PCC in Construction

Where will you find PCC on a typical site?

Foundation Base Before you place reinforcement for the footing, you pour a thin layer of PCC. It keeps the steel bars from touching the soil. It prevents moisture from seeping up. It gives you a clean, flat surface to work on.

Flooring Bed Under the tiles or marble, there is usually a 50mm to 75mm layer of PCC. It creates a hard, level base. Without it, tiles would crack over time.

Road Sub-base Village roads and internal colony roads often use PCC. It is cheaper than asphalt and lasts long under light traffic.

Drainage Channels Open drains and nallahs use PCC lining. It prevents soil erosion and keeps the channel shape intact.

Pipe Bedding When laying water or sewage pipes underground, you place them on a bed of PCC. It protects the pipe from uneven settlement.

PCC is not glamorous. Nobody takes photos of it. But a building without proper PCC will have problems within years. Settlement cracks. Damp floors. Uneven tiles.

Uses of RCC in Construction

RCC is the backbone of modern construction. You cannot build a concrete building without it.

Columns These are the vertical members that carry the load from the slab down to the foundation. RCC columns have vertical steel bars tied with lateral ties. Without steel, the column would burst under pressure.

Beams Horizontal members that span between columns. They carry the load of walls and slabs. The bottom of the beam is in tension. That is where you need the most steel.

Slabs The floor or roof you walk on. RCC slabs are reinforced in two directions usually. The steel stops the concrete from sagging and cracking.

Footings The base that spreads the building load into the ground. Even though footings are buried, they are under tremendous compression. RCC footings with proper steel reinforcement prevent structural failure.

Bridges Large span structures cannot use PCC. They need the tensile strength of RCC. The deck, piers, and abutments are all reinforced.

Water Tanks Overhead and underground tanks are made of RCC. The water pressure pushes outward. Steel reinforcement contains that pressure.

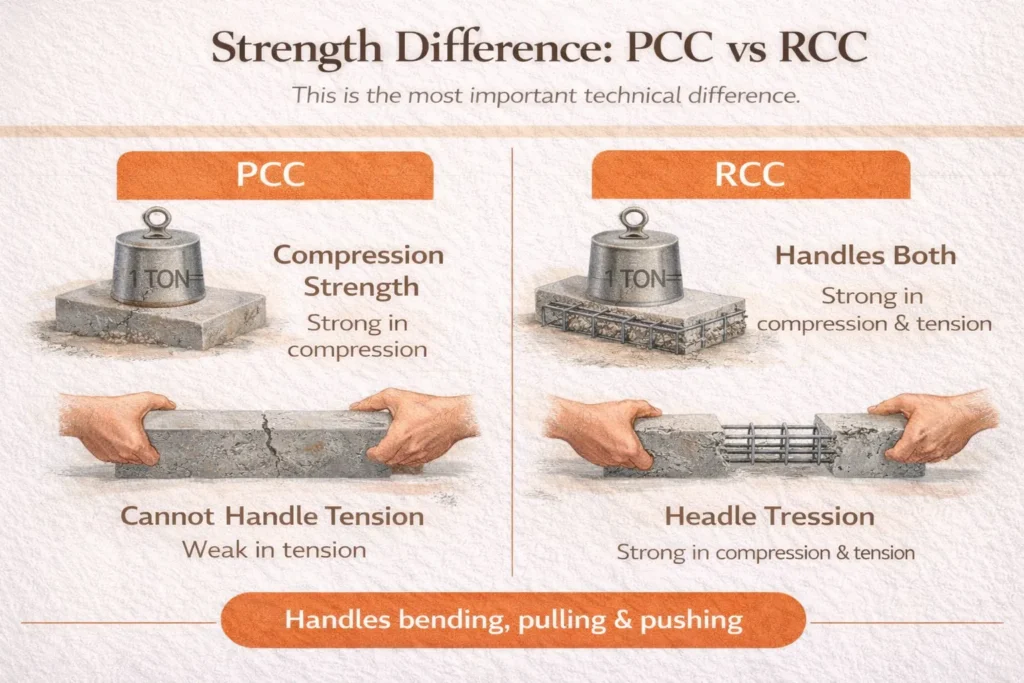

Strength Difference: PCC vs RCC

This is the most important technical difference.

PCC handles compression. Put a weight on top of a PCC block. It can take a lot of pressure before it crushes. That is compressive strength.

PCC cannot handle tension. Pull the ends of a PCC block apart. It will snap with very little force. Concrete is weak in tension. About 10 times weaker than in compression.

RCC handles both. The concrete takes the compression. The steel takes the tension. Together, they form a material that can handle bending, pulling, and pushing.

Imagine a wooden ruler. Hold it horizontally by both ends. Push down in the middle. It bends. The top surface shortens. The bottom surface stretches. If the ruler were concrete, the bottom would crack instantly. But if you glue a thin steel strip along the bottom, it holds. That is RCC.

RCC Structural Components Explained

Let us look at the main parts of an RCC structure.

RCC Slab The flat horizontal surface. Usually 100mm to 150mm thick for homes. Reinforcement runs in both directions. Main bars take the load. Distribution bars control cracking.

RCC Beam The horizontal load carrier. Rectangular shape. Reinforcement at the bottom for tension at mid-span. Reinforcement at the top for tension near supports.

RCC Column The vertical support. Square, rectangular, or circular. Longitudinal bars carry the load. Lateral ties hold the bars in place and prevent buckling.

RCC Footing The base that spreads the load. Can be isolated, combined, or raft. Reinforcement is placed at the bottom where bending occurs.

RCC Band A horizontal RCC beam provided in masonry walls. Usually at lintel level or plinth level. It binds the structure together and prevents cracks in earthquake-prone areas.

PCC Applications in Civil Engineering

Beyond basic construction, PCC has specific engineering applications.

Sub-base for Pavements Highways and airport runways have multiple layers. The bottom layer is often lean cement concrete. It is a form of PCC with low cement content.

Canal Lining To prevent water seepage, canals are lined with PCC. It reduces water loss and maintains flow velocity.

Tunnel Invert The bottom curved portion of a tunnel is cast with PCC. It provides a stable base for tracks or roadway.

Guniting and Shotcrete PCC sprayed at high velocity. Used for tunnel support, slope stabilization, and repair work.

RCC Construction Process

How is RCC actually made on site?

Step 1: Shuttering

You build a mould. Wood or steel. It holds the wet concrete in the desired shape.

Step 2: Reinforcement placement

Cut and bend steel bars as per the drawing. Tie them together with binding wire. Place cover blocks to maintain gap between steel and mould.

Step 3: Concreting

Pour the concrete mix into the mould. Do not drop it from height. Spread it evenly.

Step 4: Compaction

Use a vibrator to remove air bubbles. Air pockets are weak points. Proper compaction is non-negotiable.

Step 5: Curing

Keep the concrete wet for at least 7 days. For critical structures, 14 to 21 days. Concrete gains strength only in the presence of moisture. Dry concrete stops gaining strength.

I have seen slabs where workers forgot to cure. Within a year, hairline cracks appeared everywhere. Within five years, the slab was leaking. Curing is not optional. It is the difference between 20-year concrete and 50-year concrete.

Cost Comparison: PCC vs RCC

PCC is cheaper.

Why? No steel. No bending labour. No cover blocks. No complicated shuttering.

For a cubic metre of PCC, you pay for:

- Cement

- Sand

- Aggregate

- Mixing labour

- Placing labour

RCC is more expensive.

For a cubic metre of RCC, you pay for:

- Everything in PCC

- Steel reinforcement (major cost)

- Bar bending labour

- Binding wire

- Cover blocks

- Shuttering costs

- Vibration work

Typically, RCC costs 2.5 to 3 times more than PCC for the same volume.

But here is the thing. You cannot build a column with PCC. You cannot cast a slab with PCC. The cost is higher because the performance is higher.

Advantages of PCC

- Economical: Low cement and no steel cost.

- Easy to construct: No complex reinforcement work.

- Quick execution: Large areas can be cast quickly.

- Good for mass concrete: Works well where structural strength is not critical.

- Protective layer: Prevents direct contact between steel and soil.

Advantages of RCC

- High strength: Can carry massive compressive and tensile loads.

- Durable: Lasts decades with proper cover and good concrete.

- Versatile: Can be moulded into any shape.

- Fire resistant: Concrete protects steel from heat.

- Low maintenance: No painting or treatment required like steel structures.

- Seismic resistant: Ductile failure mode gives warning before collapse.

PCC vs RCC vs Prestressed Concrete

You may also hear about prestressed concrete. Where does it fit?

PCC: No steel. Only compression. Non-structural.

RCC: Steel added. Steel and concrete work together. The steel is passive. It activates only when load is applied.

Prestressed concrete: Steel is actively tensioned before the load is applied. The steel pulls the concrete into compression. This eliminates tension cracks completely.

Used in long-span bridges, large girders, and heavy-load structures. Overkill for houses. But essential for infrastructure.

IS Code References

If you are preparing for exams or working on government projects, these codes matter.

PCC related:

- IS 456:2000 – Plain and Reinforced Concrete Code

- IS 383 – Specifications for coarse and fine aggregates

RCC related:

- IS 456:2000 – Main code for design

- IS 13920 – Ductile detailing for earthquake resistance

- IS 1893 – Criteria for earthquake resistant design

- SP 16 – Design aids for reinforced concrete

Cover requirements:

- For RCC in moderate exposure: 20mm to 30mm cover

- For foundation: 50mm cover minimum

- For severe exposure: Increase cover or use higher grade concrete

Practical Site Tips

From site experience, here are things that actually matter.

Never place RCC directly on soil. Always provide a PCC bed below footings. Steel touching soil will rust. Rust expands. Expansion cracks concrete.

Check cover before pouring. Cover blocks shift during steel tying. Check them again before concrete arrives. Exposed steel means corrosion later.

Do not vibrate excessively. Vibration removes air. Too much vibration separates the aggregate from the paste. Stop when bubbles stop appearing.

Water is not your friend. Wet concrete is easier to work with. But extra water destroys strength. Use admixtures if you need flow, not plain water.

Curing is non-negotiable. PCC needs curing too. It also gains strength with moisture. Do not neglect it just because it is non-structural.

Conclusion

PCC and RCC are not competitors. They are partners.

PCC prepares the ground. It creates a clean, stable, protected base. It is the quiet foundation worker, unseen but essential.

RCC builds the structure. It carries the weight. It resists the wind. It holds everything together for decades.

A good engineer knows when to use which. Use PCC where you need support and leveling. Use RCC where you need strength and safety.

Understanding the difference between PCC and RCC is not just about passing an exam. It is about building things that last. It is about ensuring that the homes we live in, the bridges we cross, and the roads we drive on remain safe for generations.

Next time you walk into a building, look at the column. It is RCC. Look down at the floor. The tiles sit on PCC. Both are working together. Both are doing their job.

That is good engineering.

FAQ

What is PCC in construction?

PCC stands for Plain Cement Concrete. It is a mixture of cement, sand, aggregate, and water. No steel reinforcement. Used for base works, levelling, and non-structural applications.

What is RCC full form?

RCC full form is Reinforced Cement Concrete. It is concrete with embedded steel reinforcement. Used for structural members like columns, beams, slabs, and footings.

Where is PCC used?

PCC is used for foundation bedding, flooring base, road sub-base, drain lining, pipe bedding, and levelling courses.

Where is RCC used?

RCC is used for columns, beams, slabs, footings, retaining walls, bridges, water tanks, and all load-bearing structural elements.

Which is stronger, PCC or RCC?

RCC is significantly stronger. PCC has low tensile strength and cracks under tension. RCC resists both compression and tension due to steel reinforcement.

Can PCC be used for slab?

No. PCC slabs without reinforcement will crack and fail under load. All structural slabs must be RCC.

What is the minimum grade of concrete for RCC?

As per IS 456, the minimum grade for reinforced concrete is M20. For severe exposure conditions, M25 or higher is required.

Is PCC required before RCC footing?

Yes. A 50mm to 75mm thick PCC layer is mandatory below footings. It provides a clean, level surface and prevents steel from touching soil.

What is the difference between 1:4:8 and 1:3:6 PCC?

The numbers are cement : sand : aggregate. 1:4:8 has less cement and is used for mass fill and levelling. 1:3:6 has more cement and is used for flooring base and light-duty pavements.

How long should RCC be cured?

Minimum 7 days for ordinary Portland cement. For critical structures and in hot weather, 14 to 21 days is recommended. PCC should also be cured for at least 3 to 7 days.

Pryank Agrawal is the Founder and CEO of Housewise, a leading property management startup serving customers across 45 countries with operations in 22 Indian cities, including Pune, Bengaluru, Hyderabad, Chennai, Delhi NCR, and Mumbai. An engineering graduate from IIT Roorkee, Pryank brings extensive experience from the software industry. His passion for leveraging technology to solve real estate challenges led him to establish Housewise, simplifying property management for homeowners worldwide. After persistent requests from existing customers to address other challenges faced by Non-Resident Indians, he founded MostlyNRI, a dedicated portal assisting NRIs with taxation and financial asset management in India.