What is PCC in Construction? Meaning, Mix Ratio & Uses

Imagine building a house. You start by digging the ground. You see soil, maybe some loose stones. Would you build your walls directly on this? Of course not. It is uneven. It is unstable. You need a solid, flat starting point.

That is where PCC comes in. It is the quiet, unsung hero of construction. It is the strong, level base that everything else stands upon. Before the columns rise and the slabs are poured, there is PCC. This guide will explain what it is, why it matters, and how to get it right.

What is PCC in Construction?

PCC stands for Plain Cement Concrete. The name tells you exactly what it is.

It is a simple, strong mixture of four basic things: cement, sand, coarse aggregate (stone chips), and water. Mix them in the right proportions, pour it, and let it harden. What you get is a dense, grey, stone-like layer.

The key word is “Plain.” This means it has no steel bars (reinforcement) inside it. It is just the concrete itself. Think of it like a solid, monolithic block. It is strong in compression, good at handling weight pushing down on it. But it is not designed to bend or stretch like Reinforced Cement Concrete (RCC) can.

PCC Full Form in Civil Engineering

Let us clear up the abbreviations you will always hear on a construction site.

| Term | Full Form | Key Difference |

|---|---|---|

| PCC | Plain Cement Concrete | No steel reinforcement inside. |

| RCC | Reinforced Cement Concrete | Contains steel bars (reinforcement). |

Sometimes people say “cement concrete” or just “concrete.” When they talk about the layer under the footing, they are almost always referring to PCC.

PCC Meaning in the Construction Industry

So what does PCC actually do? Its role is foundational in every sense.

- The Perfect Level: The earth is never flat. PCC creates a perfectly level, smooth surface. This ensures that all the subsequent construction, like footings and columns, starts from a true and level plane. It is like using a ruler under your drawing.

- The Load Distributor: It spreads the massive weight of the building above over a wider area of soil below. This prevents sinking or uneven settlement. Imagine standing on soft sand. Now place a large, flat board under your feet. You stop sinking. PCC is that board for your building.

- The Protector: In foundations, it acts as a barrier. It stops soil moisture from seeping up into the main RCC structure. It also protects the steel reinforcement in the RCC above from direct contact with the ground, which can cause rust.

- The Strong Base: For flooring or roads, it provides a rigid, strong sub-base. It takes the wear and tear so the soil underneath does not.

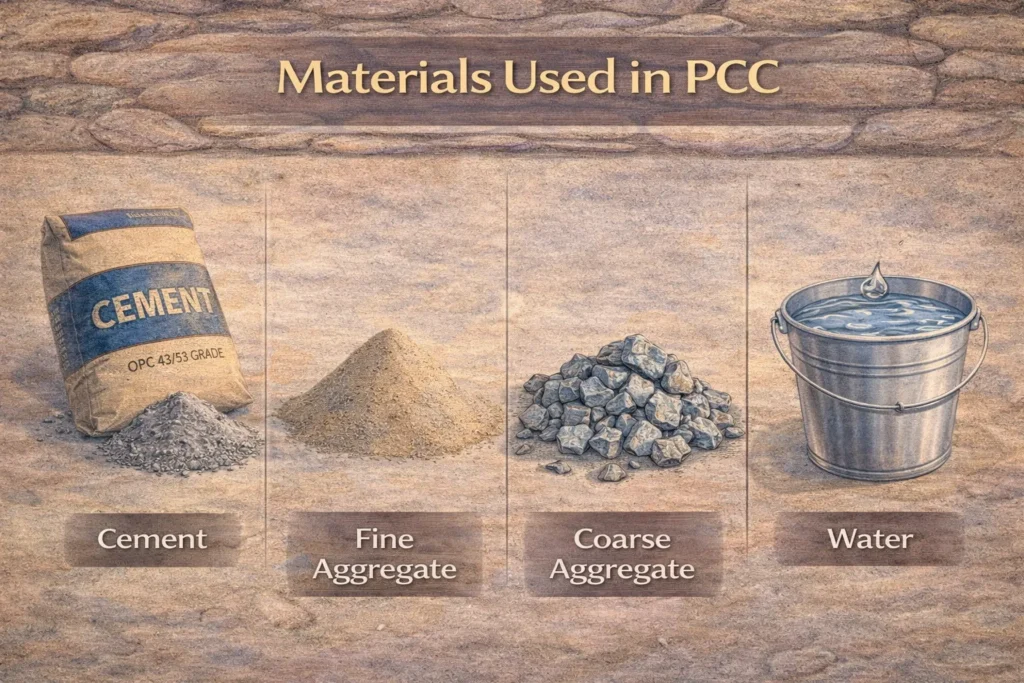

Materials Used in PCC

The recipe is simple, but the quality of ingredients matters.

- Cement: The glue. It binds everything together. Ordinary Portland Cement (OPC) 43 or 53 grade is commonly used.

- Fine Aggregate: This is sand. It fills the gaps between the cement and the larger stones.

- Coarse Aggregate: Hard, broken stone chips, usually 10mm or 20mm in size. They give PCC its bulk and major strength.

- Water: Clean, potable water is used. The right amount is crucial. Too little, and it does not mix. Too much, and the concrete becomes weak.

PCC Mix Ratios Explained

The mix ratio defines the strength and purpose of the PCC. It is written as Cement : Sand : Aggregate.

Here are the most common ones:

| PCC Ratio | Cement : Sand : Aggregate | Primary Use |

|---|---|---|

| 1:2:4 | Rich Mix | For high strength needs, like heavy machinery bases or watertight structures. |

| 1:3:6 | Medium Mix | A common, general-purpose mix for most floors and foundations. |

| 1:4:8 | Lean Mix | The standard for foundation bedding (the PCC under footings). It is economical and sufficiently strong for its load-spreading job. |

A 1:4:8 ratio means for every 1 part cement, you add 4 parts sand and 8 parts coarse aggregate. It is the workhorse of foundation work.

PCC Concrete Grade

Grades are another way to define strength. M stands for Mix, and the number is the characteristic compressive strength in MPa (MegaPascals) after 28 days.

- M5 & M7.5: Very lean mixes, used for non-structural filling.

- M10 (1:3:6): Common for flooring and pathways.

- M15 (1:2:4): Used for heavier duty paving and bases.

For most residential foundation bedding, M7.5 or M10 is perfectly adequate.

PCC Unit Weight & Density

A fully hardened PCC is heavy. Its density is approximately 2400 kilograms per cubic meter. This is useful knowledge for two reasons.

- It helps in checking quality. Significantly lighter concrete may mean it is porous or poorly mixed.

- It is crucial for structural design, as engineers need to calculate the total dead weight of the building.

Where is PCC Used?

PCC is everywhere you need a firm, level start.

- Under Foundations: Its primary job. A PCC bed is laid before pouring any footing or raft foundation.

- As Flooring: In factories, garages, and warehouses, a PCC floor is durable and cost-effective. It can be given a smooth trowel finish or a rough non-slip finish.

- In Road Construction: It serves as the rigid sub-base layer below the asphalt or concrete paving.

- For Drains and Culverts: As a bedding and surrounding layer for drainage pipes.

- PCC Soling: In landscaping and pavements, a layer of PCC is used to stabilize the ground before laying pavers or tiles.

- Making PCC Blocks: While less common now, PCC is used to make plain, non-reinforced concrete blocks for boundary walls.

PCC in Foundation Work: A Closer Look

This is its most critical application. The process is methodical.

- The soil is excavated and compacted.

- A layer of soling (like broken stones) may be placed for drainage.

- The PCC is poured directly on this. The typical thickness here ranges from 75 mm to 150 mm (about 3 to 6 inches).

- This layer does one vital thing. It provides a clean, paint-ready surface for the mason. He can now mark the exact positions of columns and walls with chalk without any soil getting in the way. It brings precision to the most crucial stage of construction.

PCC Flooring Explained

Why choose a PCC floor? It is strong, cheap, and fire-resistant. In a garage or storage shed, it handles the weight of cars and shelves easily. The thickness is usually between 75 mm and 100 mm. The surface can be finished smooth for easy cleaning or left slightly rough for better grip. It is often the base for later adding tiles or epoxy coatings.

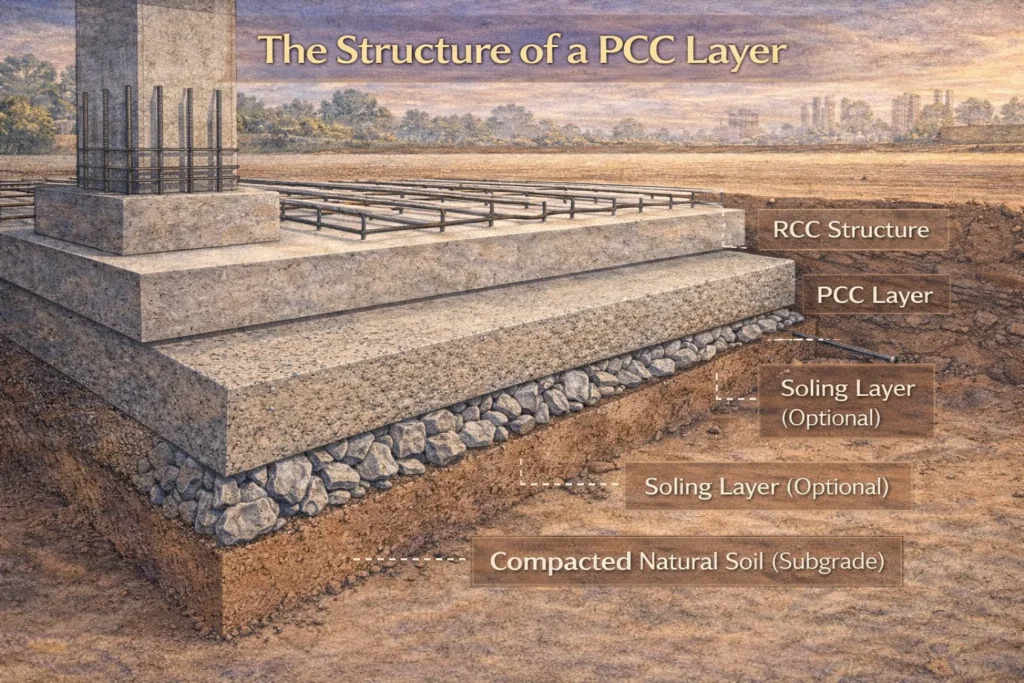

The Structure of a PCC Layer

From the ground up, a typical base looks like this:

- Compacted Natural Soil (Subgrade): The original ground, made firm.

- Soling Layer (Optional): A 100-150mm layer of hard, broken stones for drainage and stability.

- PCC Layer: Our Plain Cement Concrete, providing the final, level platform.

- RCC Structure: The main building elements like footings, columns, and slabs begin here.

PCC Thickness Standards

Getting the thickness right is a balance of strength and cost.

| Application | Typical Thickness Range |

|---|---|

| Foundation Bed | 75 mm – 150 mm |

| Internal Flooring | 75 mm – 100 mm |

| Driveway/Road Base | 100 mm – 150 mm |

For a standard house footing, a 100 mm (4 inch) thick PCC bed is very common and effective.

PCC Work Procedure on Site

Here is how it happens step-by-step on a real site:

- Preparation: The ground is cleaned, watered, and compacted. Wooden or steel shutters are fixed to define the area.

- Batching: Materials are measured by volume using gauge boxes or by weight for more accuracy.

- Mixing: Done manually with shovels on a clean platform or in a machine mixer for consistency.

- Transporting: Wheelbarrows are used to move the fresh concrete to the location.

- Pouring & Placing: Concrete is poured within the shutters. It should not be dropped from a great height.

- Compaction: A vibrator or a wooden tamping rod is used to remove air bubbles. This is crucial for strength.

- Leveling: A straight edge is moved across the top to achieve a perfectly level surface.

- Curing: The most neglected but most important step. The surface is kept wet for at least 7 days by covering it with wet gunny bags or sprinkling water. Curing allows the cement to gain its full strength slowly.

PCC vs RCC: The Clear Difference

People often confuse these two. The difference is simple but fundamental.

| Feature | PCC (Plain Cement Concrete) | RCC (Reinforced Cement Concrete) |

|---|---|---|

| Reinforcement | No steel bars. | Contains steel bars (rebar). |

| Strength Type | Strong only in compression (handles crushing). | Strong in compression AND tension (handles bending, stretching). |

| Load Bearing | Used as a base or protective layer. | Used for main structural members (beams, columns, slabs). |

| Cost | Lower, as no steel is involved. | Higher, due to the cost of steel and more skilled labor. |

| Primary Use | Foundation beds, flooring, roads. | Slabs, beams, columns, bridges, high-rise buildings. |

Analogy: PCC is like a hard chalk stick. You can press down on it, and it holds. But try to bend it, it snaps. RCC is like that chalk stick with a flexible steel wire embedded in it. Now you can bend it without it breaking. The steel handles the bending force (tension), while the concrete handles the crushing force (compression).

You cannot use PCC for a roof slab or a beam. It would crack and fail. You could use RCC for a floor, but it would be an unnecessary and expensive overkill. Each has its specific job.

How to Calculate PCC Quantity

You calculate the volume. Formula: Volume (in cubic meters) = Length (m) x Width (m) x Thickness (m).

Example: You need a foundation bed that is 10 meters long, 0.5 meters wide, and 0.1 meters (100mm) thick. Volume = 10 x 0.5 x 0.1 = 0.5 cubic meters (CUM) of PCC.

PCC Material Calculation

This is where you figure out how many cement bags, how much sand and aggregate you need. Let us calculate for 0.5 CUM of M7.5 (1:4:8 mix).

- Dry Volume: Concrete shrinks when mixed. We multiply the required volume by 1.54 to get the dry volume of materials. Dry Volume = 0.5 CUM x 1.54 = 0.77 CUM.

- Sum of Ratio: 1 + 4 + 8 = 13 parts.

- Cement Volume: (1/13) x 0.77 = 0.059 CUM.

- Number of 50 kg bags = Cement Volume / 0.035 (Volume of 1 bag) = 0.059 / 0.035 ≈ 1.7 bags. So, buy 2 bags.

- Sand Volume: (4/13) x 0.77 = 0.237 CUM.

- Aggregate Volume: (8/13) x 0.77 = 0.474 CUM.

PCC Cost Estimation

Costs vary wildly by location and material quality. But here is a basic breakdown for understanding.

- Rate per Cubic Meter: The all-in cost (material + labor) for ready-mix or site-mixed PCC (M7.5/M10 grade) can range from ₹4,500 to ₹6,500 per CUM.

- Rate per Square Foot: This depends on thickness. For a 100mm thick PCC floor, the cost with material and labor might be ₹40 to ₹60 per sq.ft.

Always get local quotes for an accurate estimate.

Codes and Standards

In India, the design and execution of concrete work, including PCC, are governed by IS 456:2000 (Plain and Reinforced Concrete – Code of Practice). Mix design can be done as per IS 10262:2019 (Concrete Mix Proportioning – Guidelines). Following these codes ensures safety and durability.

Conclusion

PCC is not glamorous. You will never see it in the finished house. But it is fundamental. It is the first solid step in turning a plan on paper into a building on the ground. Getting its mix right, its thickness right, and its execution right sets the tone for everything that follows. It is the definition of a strong foundation. Understanding PCC means you understand where true construction begins.

FAQs

What is the full form of PCC?

PCC stands for Plain Cement Concrete. This means it is a mix of cement, sand, and aggregate without any steel reinforcement (bars) inside it.

When do we use PCC in construction?

We use PCC wherever we need a strong, level, and stable base. Its most common uses are:

As a bedding layer under building foundations and footings.

For making solid floors in garages, warehouses, and sheds.

As a sub-base for roads, driveways, and pavements.

Around drainage pipes for protection and support.

What is the most common PCC mix ratio?

The 1:4:8 mix ratio is the most common for general foundation work. This means 1 part cement, 4 parts sand, and 8 parts coarse aggregate (stone chips). It provides adequate strength for load distribution at a reasonable cost.

What is the difference between PCC and RCC?

The key difference is reinforcement.

PCC has no steel bars. It is strong in compression but cracks easily under bending tension. It is used for bases and floors.

RCC (Reinforced Cement Concrete) has steel bars embedded in it. The steel handles tension (bending), and the concrete handles compression. This makes RCC suitable for structural members like columns, beams, and roof slabs.

Why is PCC laid before the main RCC foundation?

PCC serves three main purposes before the RCC foundation:

Level Surface: It creates a perfectly flat and level plane to start construction on.

Moisture Barrier: It prevents ground moisture from directly reaching the RCC foundation and its steel reinforcement.

Clean Working Platform: It provides a clean, hard surface for accurately marking the layout of columns and walls.

What is the typical thickness of a PCC layer?

The thickness depends on the use:

Under foundations: Usually 100 mm to 150 mm (about 4 to 6 inches).

For flooring: Usually 75 mm to 100 mm (about 3 to 4 inches).

For heavy loads, like machinery bases, it can be thicker.

How is the quantity of PCC calculated?

You calculate the volume. Formula: Length (m) x Width (m) x Thickness (m). For example, a 10m x 5m floor with 0.1m (100mm) thickness needs: 10 x 5 x 0.1 = 5 cubic meters of PCC.

Can PCC get hard without curing?

It will harden, but it will be weak and prone to cracking. Curing—keeping the surface wet for at least 7 days—is essential. It allows the cement to fully hydrate and gain its maximum designed strength. Skipping curing is a major mistake.

Is PCC waterproof?

Properly mixed, compacted, and cured PCC is dense and water-resistant, but it is not completely waterproof. Water can eventually seep through its tiny pores. For structures like water tanks, special waterproofing additives or membranes are required.

What happens if the PCC mix is wrong?

Using the wrong mix ratio has direct consequences: * Too lean (e.g., too much sand/aggregate): The PCC becomes weak, crumbly, and may disintegrate under load. * Too rich (e.g., too much cement): It becomes stronger but is unnecessarily expensive, and can also develop more shrinkage cracks. Always follow the specified ratio for the intended use.

Pryank Agrawal is the Founder and CEO of Housewise, a leading property management startup serving customers across 45 countries with operations in 22 Indian cities, including Pune, Bengaluru, Hyderabad, Chennai, Delhi NCR, and Mumbai. An engineering graduate from IIT Roorkee, Pryank brings extensive experience from the software industry. His passion for leveraging technology to solve real estate challenges led him to establish Housewise, simplifying property management for homeowners worldwide. After persistent requests from existing customers to address other challenges faced by Non-Resident Indians, he founded MostlyNRI, a dedicated portal assisting NRIs with taxation and financial asset management in India.